Innovation & Consistent Reliable Technologies

Europoxy FZCO is an ISO 9001: 2015 certified company founded on the well-built principles of innovation and consistent, reliable technologies. A pioneer in the region, and to this day the only local manufacturer of epoxy product, with the first fully automatic casting plant in MENA Region, we take our commitment to the international. market seriously.

Facilities & Equipments

THE CASTING PLANT

Europoxy has latest generation of processing plant with state of art technology from headrich Vacuum Systems Germany.

CLAMPING MACHINES

Several Sophisticated APG clamping machines from company vogel GmbH & Co.KG Switzerland,are installed with different force.

Great reason for the people

choose us

The only GCC manufacturer with 15+ years of expertise and a flawless record.

Performance oriented Management and Technical Team.

Latest generation processing plants with Hedrick Vacuum Systems Germany technology.

Highest competence in producing specialised, custom-made products.

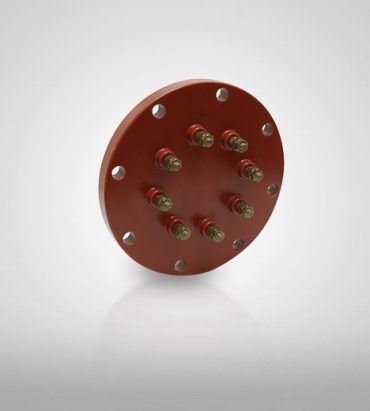

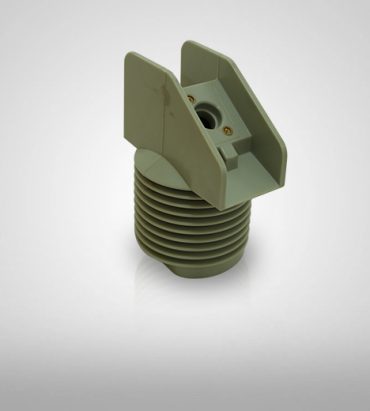

OUR PRODUCTS

100+

Industries Served80+

Client Serving20+

Year Experience40+

Countries SuppliedHistory of Europoxy FZCO

Our FAQ's